What are blanchers and pasteurizers?

Progressu is all about making your food processing smooth and easy, with specialties and requirements of your desires. Here, we are going to discuss blanchers and pasteurizers. Let’s start with blanchers.

Blanching is a cooking process that is used to enhance the color, flavor, and texture of food items.

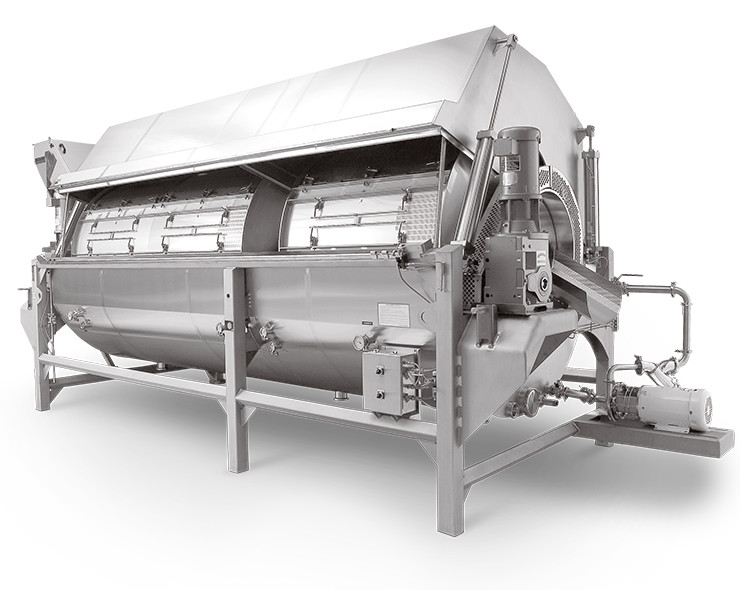

A blancher machine is made to quickly cook food items especially vegetables in boiling water or steams before plunging them into a cold bath. Some common types of blanchers are available nowadays. These types include belt blanchers, drum blanchers, and screw blanchers.

Blanchers are meant to use heat in the processing of fruits and vegetables for cleaning and cooking before performing other processing activities such as freezing and canning. This heating process involves inclusion or dipping of products in hot water steam, or other liquids, one by one or through making a batch of goods.

Multifunctional

The blanching process removes sugars, starches, and trapped gasses, and reduces the chances of microbes to avoid malfunctioning of food products. The majority of blanchers available in the market nowadays either use a steam belt or rotary drum technology. Steam blanchers are preferred because they retain solids and nutrients and yield crispier and fresher-looking food products. These blanchers leave less water on products which is a mandatory condition for freezing operations.

Pasteurization

Pasteurization is a process that involves heating every item of the food product to destroy pathogens like bacteria, and avoid any malfunctioning of that food item. The heat quantity, time to apply, and treatment system to be used depending on the properties of the product, and hence the desired results are achieved with perfection. Progressu offers you efficient solutions to cater to all your requirements regarding pasteurization.

By assessing your product, its quality, heat bearing capacity, and the desired shelf life, you may choose various methods of heat treatment including short-time – high-temperature heating (STHT), high temperature – short time (HTST), or ultra-high temperature process (UHT) with applications of indirect or direct heating. These are all done by using pasteurizers that are manufactured by quality manufacturers. Progressu offers you help in choosing the right one for you according to your requirements.

The idea behind the pasteurization and blanching process is to serve the much-needed action of inactivating bacterial action, which, in turn, prevents quick destruction of the food product and maintain its energized taste and quality. These products are processed to preserve their shelf-life, which was not sufficient to store these products at room temperature before.